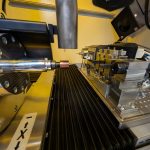

The MTC (Micro Turning Center) series of machines was designed according to the needs of ultra-precision turning. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, metals and plastics. Thus, in combination with the C-axis (option), allowing for the turning of nonrotationally symmetric / free-form workpieces (Slow Tool).

An optional tool setting camera can be mounted to the main spindle housing, using an industrial pallet system for the connection, to allow for an easy and accurate remounting. Tool holders and a mechanical interface for the in process camera, as well as different measuring devices like 3D-touchprobes or LVDTs can be mounted to the Z-slide.

When using the rotary table (option), its faceplate is used to mount all the tooling and measurement equipment, offering additional capabilities to the system, such as using the B-axis as a tool turret. The rotary table can also be used to keep a constant cutting point on the tool (3-axis machining, Single Point Turning). Furthermore, the rotary B-axis can be used to selectively change the cutting point if the tool is worn out.

Besides many other accessories, that make the MTC series an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs.

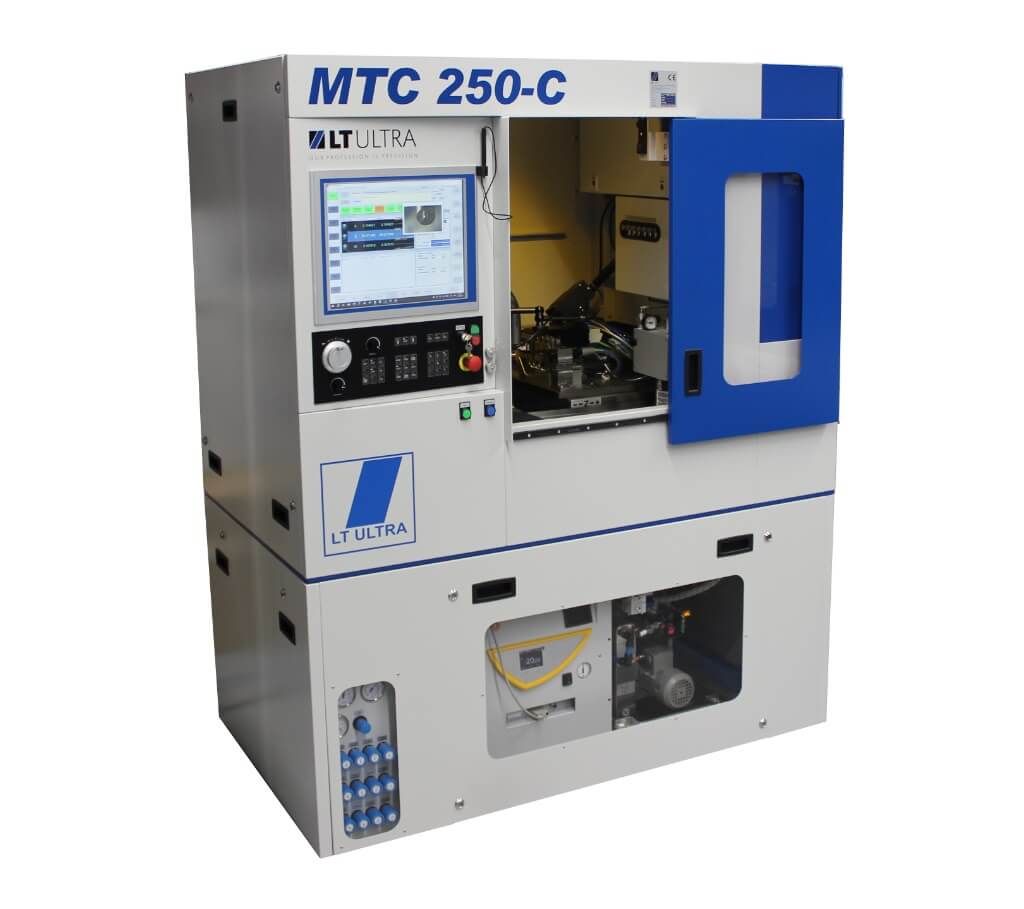

MTC 250-Compact

- Hydrostatic (oil) guides for X and Z axes

- Natural granite construction

- Active leveling and vibration isolation

- Workpiece measurement system (form correction)

- Integrated tool measurement system

- Camera for process monitoring

- Form accuracy: up to << 100 nm

- Surface roughness: down to < 2 nm (Ra), depending on the workpiece

- Compact footprint of only ~2 m² (including hydraulic system, temperature control units, and control cabinet)

The ultra-precision turning machine (UP lathe) MTC 250 Compact features a more compact cabin design compared to our MTC 250. Additionally, the control panel is integrated into the cabin, and the travel range in the X-direction has been extended by 100 mm to a total of 350 mm.

This machine series was originally developed for the production of IOLs (intraocular lenses), but it is also well-suited for all other compact workpieces.

Typically, up to 7 tools can be used for workpieces up to 30 mm in diameter. Alternatively, instead of a tool holder, a chromatic confocal sensor can be integrated for in-line measurement of the workpiece, or one of our FTAs (Fast Tool Axes) for ultra-fast machining of freeform surfaces. A compact milling spindle can also be added to expand the manufacturing capabilities.

A typical configuration for machining hydrophobic and hydrophilic small workpieces includes:

- Automatic workpiece collet chuck

- FTA (Fast Tool Axis) with 2 tools

- Up to 6 tool holders

- Milling spindle

- Tool measurement system

- Automatic height adjustment for tools

- Cryogenic cooling

- Rear side with automatic sliding door

- Integration into robotic cell

- Chip extraction system

- Integrated temperature control for spindle and hydraulics

- Process monitoring camera

- Minimum quantity lubrication, including flow sensor

- Barcode scanning of production orders

- OPC-UA data interface

The foundation of the MTC 250 is a T-shaped natural granite structure. The slides of the X and Z axes, as well as the housing of the main spindle, are also made of natural granite. The linear axes are hydrostatically mounted (oil-based).

Mounted on the X-slide, the main spindle features aerostatic bearings and comes standard with a rotational speed of 10,000 rpm.

In addition to the configurations already mentioned, we naturally offer a wide range of further options. Feel free to contact us!

| Control: | Delta Tau Power Pmac |

| CNC-axes: | X, Z and C (plus Y for automatic tool height adjustment) |

| Bearing design: | Hydrostatic (oil) bearing |

| Drive system: | X- and Z-axis linear motor, B-Axis torque motor |

| Travel: | X-axis= 350 mm Z-axis= 250 mm |

| Speed: | X- and Z-axis max. 5000 mm/min |

| Stiffness: | 600 N/μm |

| Linear scales: | Resolution < 0,009 nm |

| Bearing type: | Air bearing |

| Drive system: | DC servo motor |

| Speed: | max. 10000 RPM |

-

- C-axis for non-circular and freeform machining with dynamic axis mode (slow-tool)

- Fast Tool Axis (FTA)

- Process monitoring camera

- Tool measurement system

- Automatic tool height adjustment (Y-axis)

- Workpiece measurement system (form correction)

- Minimum quantity lubrication system, including flow sensor

- Balancing software

- 3D probe

- Automatic workpiece collet chuck

- Milling spindle

- Up to 7 tool holders

- Cryogenic cooling

- Rear side with automatic sliding door

- Integration into robotic cell

- Chip extraction system

- Barcode scanning of production orders

- OPC-UA data interface

- …and many more optional accessories available upon request.

MTC

MTC 250

| Control: | Delta Tau Power Pmac |

| CNC-axes: | X, Z and B, C |

| Bearing design: | Hydrostatic (oil) bearing |

| Drive system: | X- and Z-axis linear motor, B-Axis torque motor |

| Travel: | X- and Z-axis= 250 mm |

| Speed: | X- and Z-axis max. 5000 mm/min |

| Stiffness: | 600 N/μm |

| Linear scales: | Resolution < 0,009 nm |

| Bearing type: | Hydrostatic (oil) bearing |

| Drive system: | Brushless DC motor |

| Rotation angle: | 360° |

| Speed: | max. 10 RPM |

| Bearing type: | Air bearing |

| Drive system: | DC servo motor |

| Speed: | Spindle max. 4000 RPM and 2300 RPM in C-axis mode, optional max. 10000 RPM and 3000 RPM in C-axis mode |

| Ø over bed: | Ø 230 mm (Ø 500 mm with B-axis or optional) |

-

- C-axis for out of round- / freeform-machining with dynamic axis system (Slow Tool)

- Fast tool axis

- Process monitoring camera

- Tool measuring system

- Workpiece form measuring system

- Minimum quantity lubrication

- B-Axis

- Balancing Software

- 3D-touch probe

MTC

- Hydrostatic (0il) bearings

- Granite machine base

- Active machine leveling and active vibration isolation system

- Form measuring system

- Integrated tool measuring system

- Process camera

- Form tolerance: < 150 nm within 100 mm dia.

- Roughness: < 2 nm (Ra)

The ultraprecision turning machine (UP-Turning machine) MTC 250 (Micro Turning Center) has a lightweight construction of the moving parts and thus enables the machine axes to be used in a dynamic mode (Slow Tool). This machine is our standard machine with the smallest footprint.

The travelling distances of the X- and Z-axis are 250 mm and provide the machining of workpieces up to 500 mm in diameter.

The MTC 250 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide.

Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

MTC 350

- Hydrostatic (0il) bearings

- Granite machine base

- Active machine leveling and active vibration isolation system

- Form measuring system

- Integrated tool measuring system

- Process camera

- Form tolerance: < 150 nm within 100 mm dia.

- Roughness: < 2 nm (Ra)

The ultraprecision turning machine (UP-Turning machine) MTC 350 (Micro Turning Center) combines dynamic use with an increased work space, thus resulting in a wide range of products to be manufactured.

The travelling distances of the X- and Z-axis are 350 mm and provide the machining of workpieces up to 700 mm in diameter.

The MTC 350 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. In addition to the X- and Z-axis there is the option to have an additional linear axis. This A-axis allows to do micro milling or raster flycutting operations on the machine.

Besides many other accessories, that make the MTC 350 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

| Control: | Delta Tau Power Pmac |

| CNC-axes: | X, Z and B, C |

| Bearing design: | Hydrostatic (oil) bearing |

| Drive system: | X-, Y- and Z-axis linear motor, B-axis torque motor |

| Travel: | X- and Z-axis = 350 mm, Y-axis = 160 mm |

| Speed: | X-, Y- and Z-axis max. 5000 mm/min |

| Stiffnes: | 600 N/μm |

| Linear scales: | Resolution< 0,009 nm |

| Bearing Type: | Hydrostatic (oil) bearing |

| Drive system: | Brushless DC motor |

| Rotation angle: | 360° |

| Speed: | max. 10 RPM |

| Bearing Type: | Air bearing |

| Drive system: | DC servo motor |

| Speed: | Spindle max. 4000 RPM and 2300 RPM in C-axis mode, optional max. 10000 RPM and 3000 RPM in C-axis mode |

| Ø over bed: | Ø 380 mm (Ø 700 mm with B-axis or optional) |

-

- C-axis for out of round- / freeform-machining with dynamic axis system (Slow Tool)

- Fast tool axis

- Process monitoring camera

- Tool measuring system

- Workpiece form measuring system

- Minimum quantity lubrication

- B-axis

- Balancing Software

- 3D-touch probe

MTC

MTC 650

| Control: | Delta Tau Power Pmac |

| CNC-axes: | X, Z and B, C |

| Bearing design: | hydrostatic (oil) bearing |

| Drive system: | X- and Z-axis linear motor, B-axis torque motor |

| Travel: | X- and Z-axis = 650 mm |

| Speed: | X- and Z-axis max. 2000 mm/min |

| Stiffness: | 800 N/μm |

| Linear scales: | Resolution < 0,009 nm |

| Bearing type: | hydrostatic (oil) bearing |

| Drive system: | brushless DC motor |

| Rotation angle: | 360° |

| Speed: | max. 10 RPM |

| Bearing type: | air bearing |

| Drive system: | DC servo motor |

| Speed: | Spindle max. 10000 RPM and 1500 RPM in C-axis mode |

| Workpiece weight: | 200 kg |

| Ø over bed: | Ø 800 mm (option Ø 1000 mm) |

-

- C-axis for out of round- / freeform-machining with dynamic axis system (Slow Tool)

- Fast tool axis

- Process monitoring camera

- Tool measuring system

- Workpiece form measuring system

- Minimum quantity lubrication

- B-axis

- 3D-touch probe

MTC

- Single point turning

- Hydrostatic (0il) bearings

- Granite machine base

- Active machine leveling and vibration isolation system

- Form measuring system

- Integrated tool measuring system

- Process camera

- Form tolerance: < 100 nm within 100 mm dia.

- Roughness: < 2 nm (Ra)

The ultraprecision turning machine (UP-Turning machine) MTC 650 is currently our largest series machine. Our customers can machine workpieces up to 200 kg in UP quality.

The travelling distances are 400 mm in the Z-axis and 650 mm in the X-axis. Workpieces with a diameter of up to 800 mm in diameter (optionally 1000 mm) can be machined. The extended X travel offers more space for additional accessories, further tool holders or special bodies/ constructions.

The MTC 6500 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available.

Besides many other accessories, that make the MTC 650 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

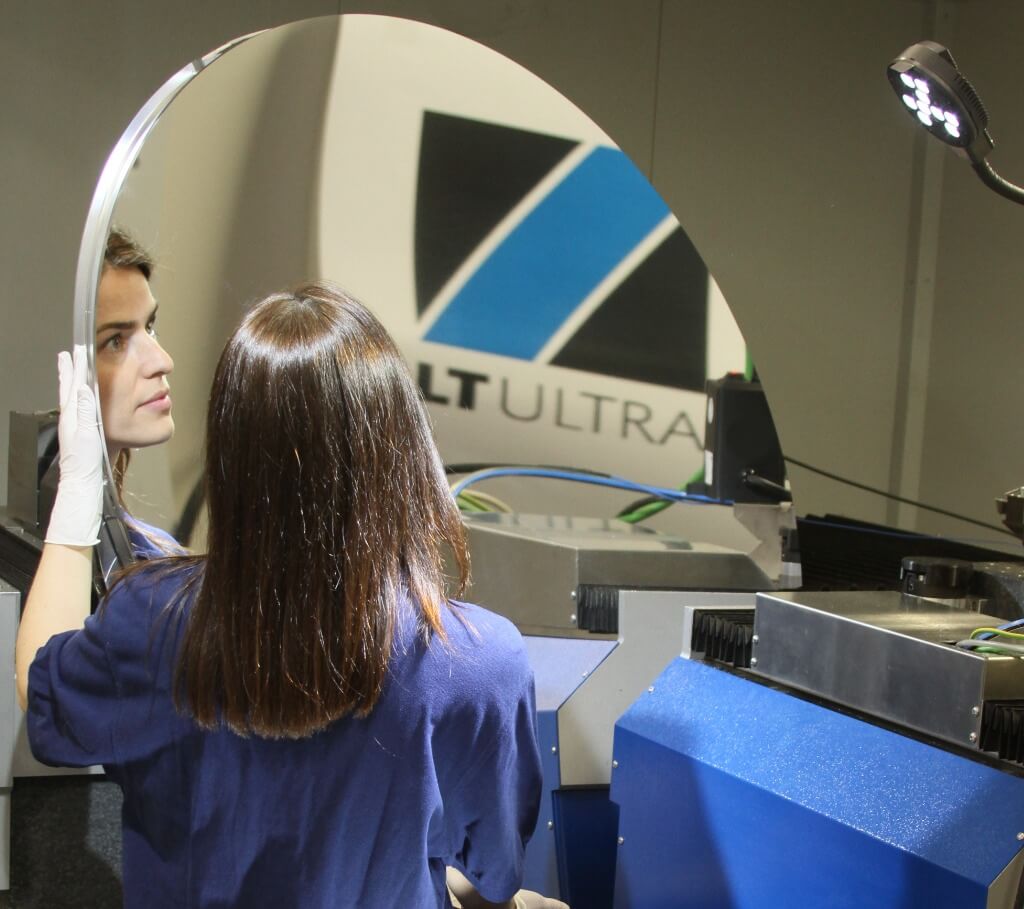

MTC 1800

The ultra-precision turning machine (UP lathe) MTC 1800 is not only our largest lathe, but currently also the world’s largest horizontal UP turning machine!

Our customers can machine workpieces with diameters of up to 2000 mm and weights of several hundred kilograms in ultra-precision quality.

Despite the large workpiece dimensions, the system is optimized for dynamic axis mode (slow-tool). This is achieved through a multi-stage Z-axis design: a long Z-axis (> 600 mm) handles pre-positioning, while a short Z-axis (> 170 mm) performs the stroke movements.

The aerostatically mounted main spindle has been optimized for higher loads and, as with the MTC 650, is mounted on the X-slide with a travel range of 700 mm (optionally > 1000 mm).

Among other applications, the first machine of this series was used to manufacture mirrors for the ARIEL space mission.

The series can be freely configured with our wide range of options. One configuration that has proven itself in our own contract manufacturing includes:

- Machine interior temperature control, with temperature stability of up to < 20 mK

- Extensive temperature monitoring and logging

- Workpiece measurement using LVDT or chromatic confocal sensor

- Machine dampers for floor vibration isolation, based on multi-chamber technology

- Machine cabin with large door for easy loading of workpieces via overhead crane

- Process monitoring camera

Of course, the machine can be supplemented with many additional accessories, which we would be happy to present to you in a personal consultation.

| Control: | Delta Tau Power Pmac |

| CNC-axes: | X, Z1, Z2 and C |

| Bearing design: | hydrostatic (oil) bearing |

| Drive system: | X- and Z-axis linear motor |

| Fahrwege: | X-axis= 700 mm optional > 1000 mm Z1-axis= 170 mm Z2-axis > 600 mm |

| Bearing type: | air bearing |

| Drive system: | DC servo motor |

- C-axis for non-circular and freeform machining with dynamic axis mode (slow-tool)

- Process monitoring camera

- Workpiece measurement system (form correction)

- Balancing software

- Minimum quantity lubrication system

- 3D probe

- …and many more options available upon request.

MTC

Contact person

| First name: | Richard |

| Last name: | Widemann |

| Responsible for: | UP-technology, service |

| Phone: | +49 (0) 7552 – 4 05 99-80 |