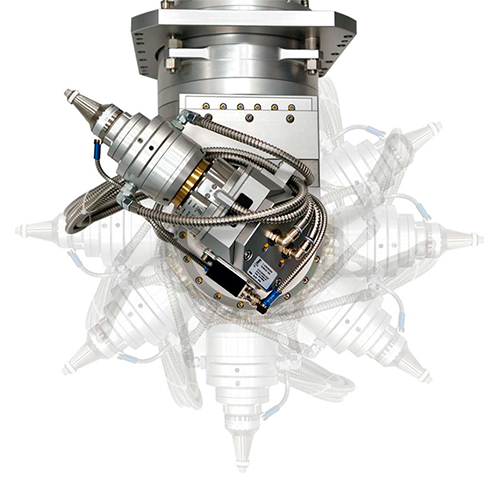

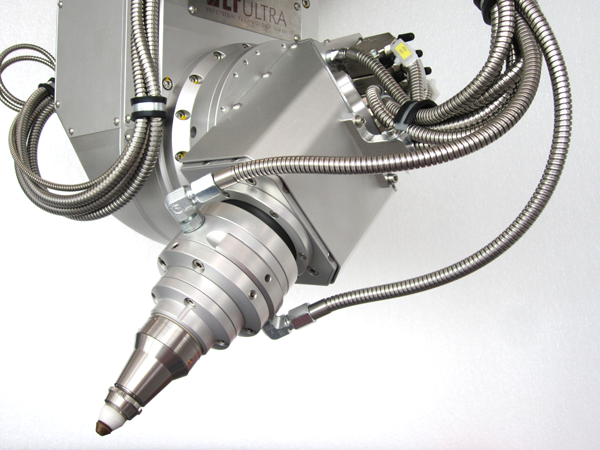

3D-1 Laser swivelhead

| Motor | Torquemotor |

| Swivelrange / stroke | +/- 135° (+/- 160°) |

| Speed max. | 60 1/min |

| Acceleration | 3600°/s² |

| Position accuracy | 10” |

| Clear aperture | Ø40(60)mm |

| Max. Torgue | 15 Nm |

| Continuous force | – |

| Motor | Torquemotor |

| Swivelrange / stroke | +/- 17,5mm |

| Speed max. | 30 m/min |

| Acceleration | >40 m/s² |

| Position accuracy | +/- 10µm |

| Clear aperture | Ø32mm |

| Max. Torgue | – |

| Continuous force | > 100 N |

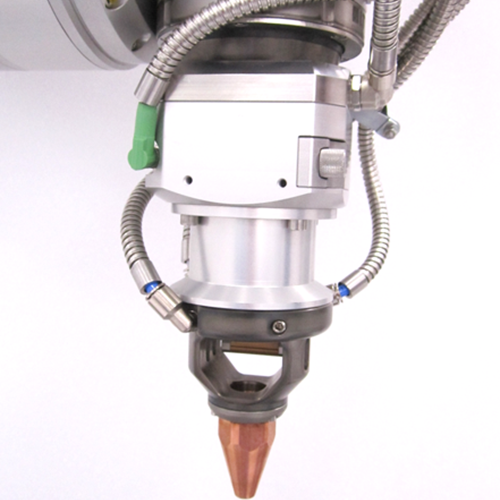

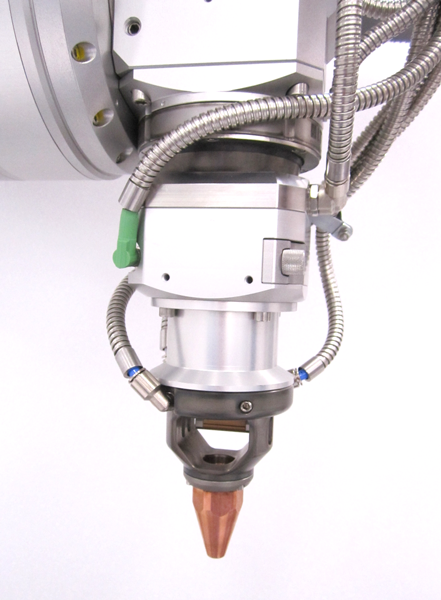

SH35

Laser swivel head SH3D-1 / SLH3D-2

Application: Phase cutting of tubes, laser welding, laser drilling

SD is our short cut for a laser head consisting of either the swivel axis only or in combination with a highly dynamic linear axis for laser processing of pipes.

Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing.

The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

The clear aperture of the current laser swivel head SH35 is 35mm, the larger version SH60 is still available with a clear aperture of 60mm. When a solid state laser is used, optical components with 1.5 “and 2” are available and protective glass cassettes on both the collimator side and the pressure seal below the focusing lens protect the optics from contamination.

There is also the option of replacing one of the standard optics with a special unit in order to realize the use of a camera.

Various applications can be operated by means of processing units for cutting or welding; alternatively, a more torque-intensive version of the pivot axis is available for welding applications.

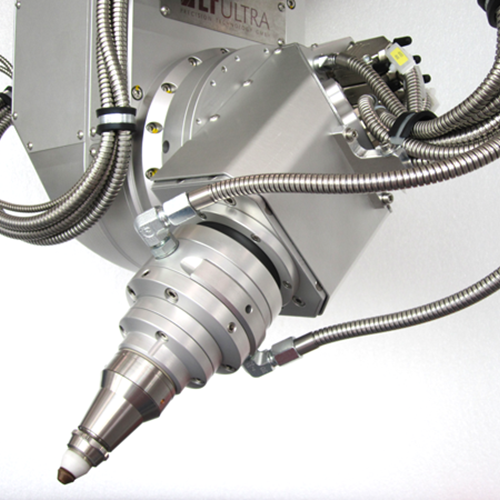

3D-2 Laser rotary swivel head

Laser rotary swivel head RSH 3D-2

Application: Laser cutting / laser welding of 3D components

RSD is our short name for a laser head consisting of a total of 2 motorized axes for use in large-format laser machines in gantry design for 3-dimensional laser cutting / laser welding of components.

The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals.

Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing.

The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Our highly dynamic version (RSLH35) with significantly reduced masses has been available since 2017; alternatively, the laser rotary swivel head RSLH60 is still available for the use of larger apertures.

When using a solid-state laser, optical components with 1.5 “and 2” are available and protective glass cassettes on both the collimator side and the pressure seal below the focusing lens protect the optics from contamination. There is also the option of replacing one of the standard optics with a special unit in order to realize the use of a camera.

Various applications can be operated by means of processing units for cutting or welding; alternatively, a more torque-intensive version of the swivel axis (RSH60) is available for welding applications.

| Motor | Torquemotor |

| Swivel range / stroke | endless |

| Speed max. | 120 1/min |

| Acceleration | 20 1/s² |

| Position accuracy | 10” |

| Clear aperture | Ø60mm |

| Torque | >36 Nm |

| Continuous force | – |

| Motor | Torquemotor |

| Swivel range / stroke | +/- 135° |

| Speed max. | 120 1/min |

| Acceleration | 30 1/s² |

| Position accuracy | 10” |

| Clear aperture | Ø60mm |

| Torque | >10 Nm |

| Continuous force | – |

| Motor | Torquemotor |

| Swivel range / stroke | n x 360° (endless) |

| Speed max. | 60 1/min |

| Acceleration | 10 1/s² |

| Position accuracy | 10” |

| Clear aperture | Ø60mm |

| Torque | >50 Nm |

| Continuous force | – |

| Motor | Torquemotor |

| Swivel range / stroke | +/- 135° (+/- 160°) |

| Speed max. | 60 1/min |

| Acceleration | 10 1/s² |

| Position accuracy | 10” |

| Clear aperture | Ø60mm |

| Torque | >15 Nm (38Nm) |

| Continuous force | – |

RSH35

3D-3 Laser rotary swivel head

| Motor | Torquemotor |

| Swivel range / stroke | endless |

| Speed max. | 120 1/min |

| Acceleration | 20 1/s² |

| Position accuracy | 10” |

| Clear aperture | Ø60mm |

| Torque | >36 Nm |

| Continuous force | – |

| Motor | Torquemotor |

| Swivel range / stroke | +/- 135° (+/- 160°) |

| Speed max. | 120 1/min |

| Acceleration | 30 1/s² |

| Position accuracy | 10” |

| Clear aperture | Ø60mm |

| Torque | 10 Nm |

| Continuous force | – |

| Motor | Torquemotor |

| Swivel range / stroke | +/- 17,5mm (+/- 10mm) |

| Speed max. | 20 m/min |

| Acceleration | 35 m/s² |

| Position accuracy | +/- 10µm |

| Clear aperture | Ø32mm |

| Torque | – |

| Continuous force | > 100 N |

| Motor | Torquemotor |

| Swivel range / stroke | n x 360° (endless) |

| Speed max. | 60 1/min |

| Acceleration | 10 1//s² |

| Position accuracy | 10” |

| Clear aperture | Ø60mm |

| Torque | >50 Nm |

| Continuous force | – |

| Motor | Torquemotor |

| Swivel range / stroke | +/- 135° (+/- 160°) |

| Speed max. | 60 1/min |

| Acceleration | 10 1/s² |

| Position accuracy | 10” |

| Clear aperture | Ø60mm |

| Torque | 15 Nm |

| Continuous force | – |

| Motor | Torquemotor |

| Swivel range / stroke | +/- 17,5mm |

| Speed max. | 30 m/min |

| Acceleration | > 35 m/s² |

| Position accuracy | +/- 10µm |

| Clear aperture | Ø32mm |

| Torque | – |

| Continuous force | > 100 N |

RSLH35

Laser rotary swivel head RSLH 3D-3

Application: Angular cutting, 3D-laser processing of components

RSLD is our short cut for a laser head consisting of a total of 3 motorized axes for use in large-format laser machines in gantry design for the 3-dimensional laser cutting of components.

The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals.

Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with low-absorption coating or alternatively glass optics. The use of an adaptive optics enables the freely programmable focus position for cutting and piercing.

The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Our highly dynamic version (RSLH35) with significantly reduced masses has been available since 2017; alternatively, the laser rotary swivel head RSLH60 is still available for the use of larger apertures.

When using a solid-state laser, optical components with 1.5 “and 2” are available and protective glass cassettes on both the collimator side and the pressure seal below the focusing lens protect the optics from contamination. There is also the option of replacing one of the standard optics with a special unit in order to realize the use of a camera.

Contact person

| First name: | Dietmar |

| Last name: | Bischof |

| Responsible for: | Beam guidance |

| Phone: | +49 (0) 7552 – 4 05 99-70 |